The Solution: Three Core Pillars

We solve the "Black Hole" of manufacturing with a system built on three non-negotiable principles.

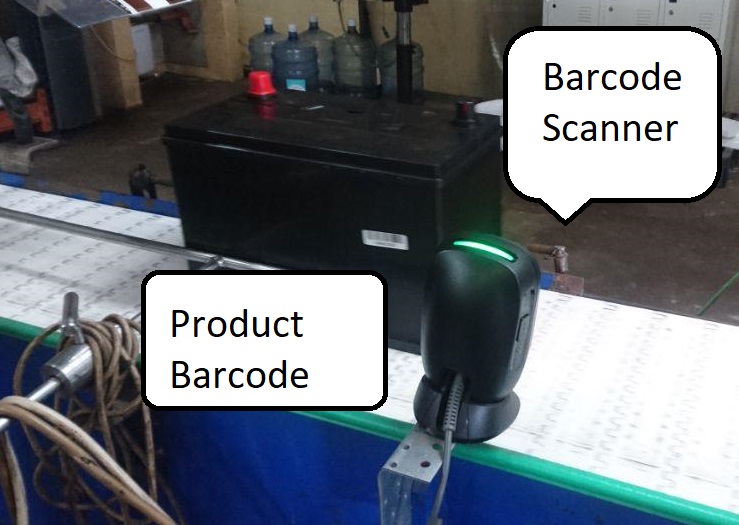

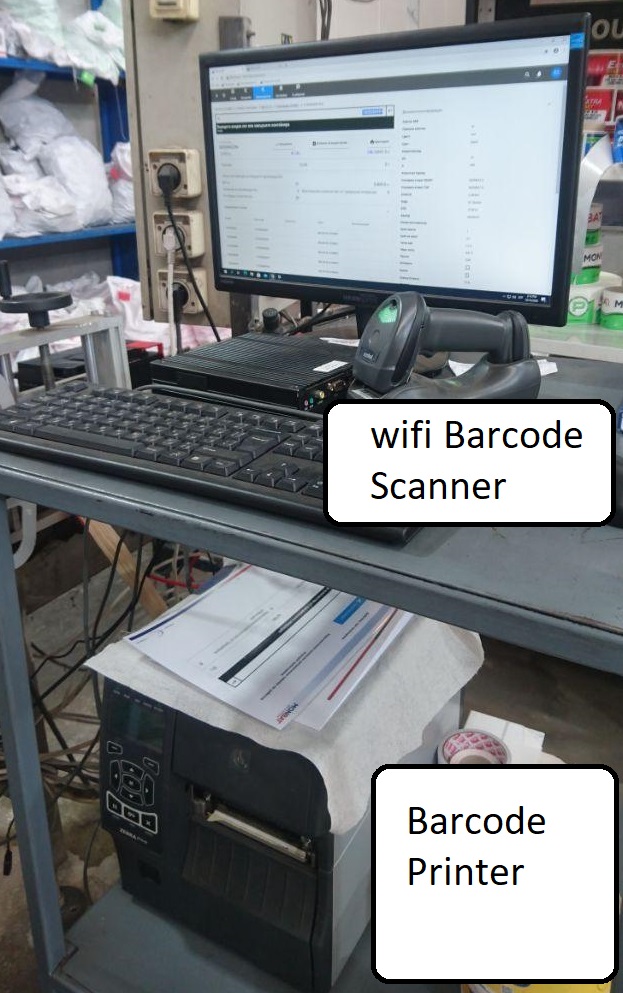

Barcode-Driven Traceability

Barcode-Driven. We stop asking people to type. We ask them to scan. Scanning is faster and 99.9% accurate.

- ✓ Material movement captured

- ✓ Zero data entry errors

- ✓ FIFO/FEFO enforcement

Intelligent Validation & Guidance

Validation & Guidance. The system knows the rules. If an operator tries to use the wrong material, the system stops them.

- ✓ Guides operators step-by-step

- ✓ Prevents costly mistakes

- ✓ Real-time validation

Seamless ERP Integration

Open Architecture. We play nice with others. Keep your accounting system; we'll feed it accurate execution data.

- ✓ API-first integration

- ✓ Connects with SAP, QuickBooks

- ✓ Bidirectional sync

AI-Ready from Day One

Everyone wants AI, but AI eats data. If your data is manual entry garbage, your AI will be garbage. TAKT ERP builds the clean, structured dataset you need to use AI tomorrow.

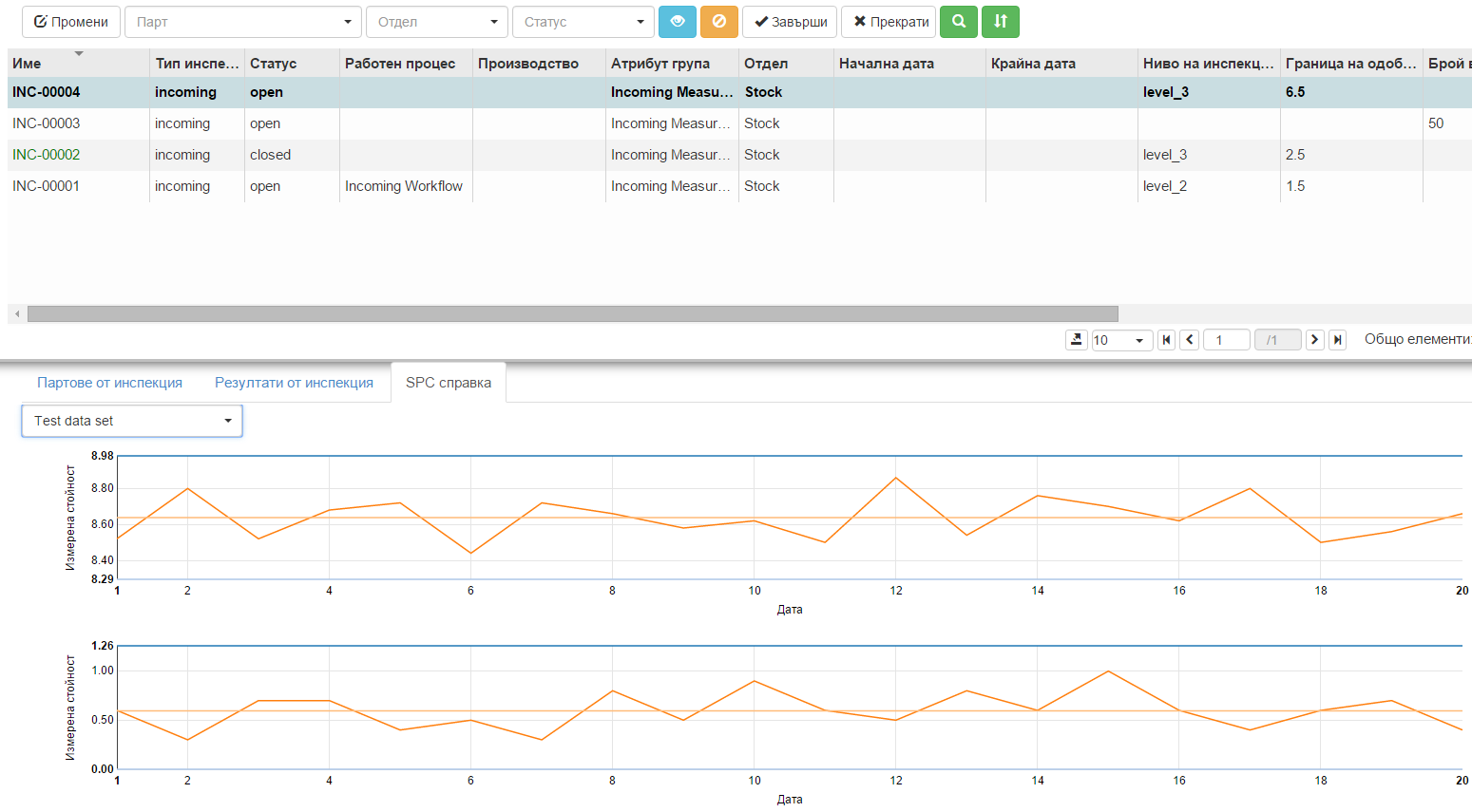

Predictive Quality

Detect defect patterns early and prevent issues before occurrence.

Demand Forecasting

AI learns actual capacity and predicts accurate lead times.

Predictive Maintenance

Analyze usage data to predict failures before they stop production.

Process Optimization

AI continuously finds inefficiencies in your workflows.

Predictive Analytics

Barcode Scanner

Shop Floor Scanning

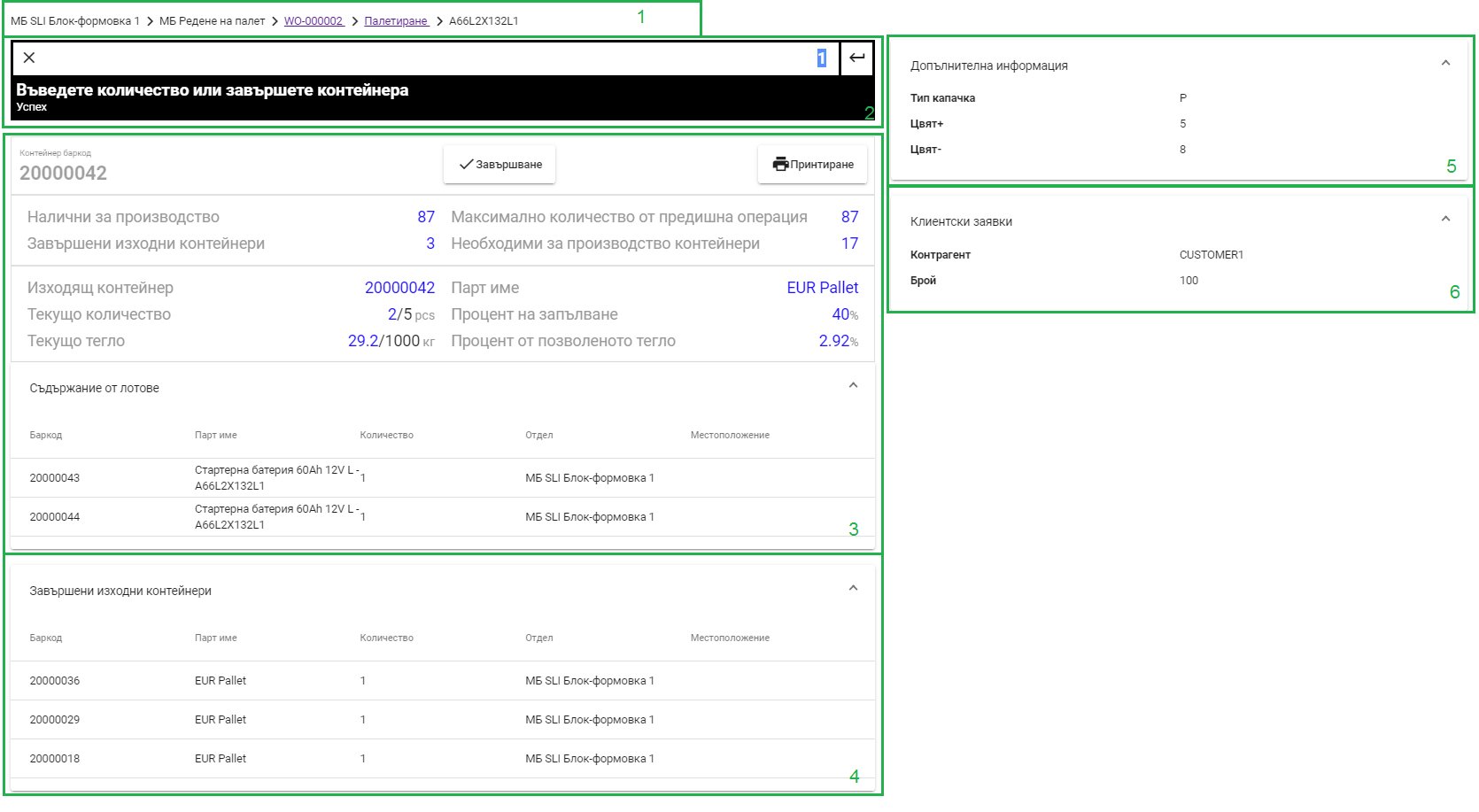

Pillar 1: Barcode-Driven Traceability

The backbone of data integrity. Nothing enters, moves, or leaves without a digital ID.

Inbound & Labeling

Receive materials, validate quantities, and generate internal barcodes immediately. Full traceability begins at the dock.

Process Tracking

Every operator action requires a scan: Work Order → Material → Output. No guesswork.

Automatic Compliance

FIFO/FEFO is enforced automatically. The system physically prevents operators from using expired or wrong materials.

Intelligence & Integration

A virtual supervisor that watches every step, connected seamlessly to your business ecosystem.

Intelligence Built In

- Role-Based Guidance: Context-aware interface shows operators exactly what they need to do next.

- Prescriptive Alerts: "Wrong material detected", "FIFO violation" - catches errors before they happen.

- Validation: Nothing is committed without passing system checks.

Integration Without Replacement

- Keep Your Finance System: We handle manufacturing; your existing ERP/Accounting handles the books.

- API-First: Real-time, bidirectional data exchange.

Operator Guidance

Workstation Setup

Complete ERP Capabilities

Beyond MES, TAKT provides the essential modules to run your manufacturing business.

Sales

Customer order management, custom attributes per order, delivery commitments, and pricing.

Purchasing

MRP-driven purchase orders, supplier management, multi-line POs, and delivery tracking.

Inventory

Real-time stock tracking, multi-location management, lot traceability, and stock movements.

Production

Work orders, BOM management, routing, scheduling, and shop floor execution.