The True Cost of Manual Data Entry (and How to Eliminate It)

In an era of self-driving cars, generative AI, and lights-out factories, it is genuinely shocking how many manufacturing operations still run on the "Clipboard Operating System."

Walk the floor of a typical mid-sized factory, and you will see it everywhere: operators scribbling numbers on paper travelers, supervisors manually tallying production counts on whiteboards, and administrative staff spending their mornings typing yesterday's log sheets into Excel.

Many manufacturers view manual data entry as a "necessary evil" or, worse, a low-cost alternative to buying software. After all, paper is cheap, and you already pay the employees, right?

Wrong. Paper is arguably the most expensive technology you can use in a modern factory. When you account for the hidden costs of errors, delays, lack of visibility, and lost opportunity, the price tag of manual entry is staggering.

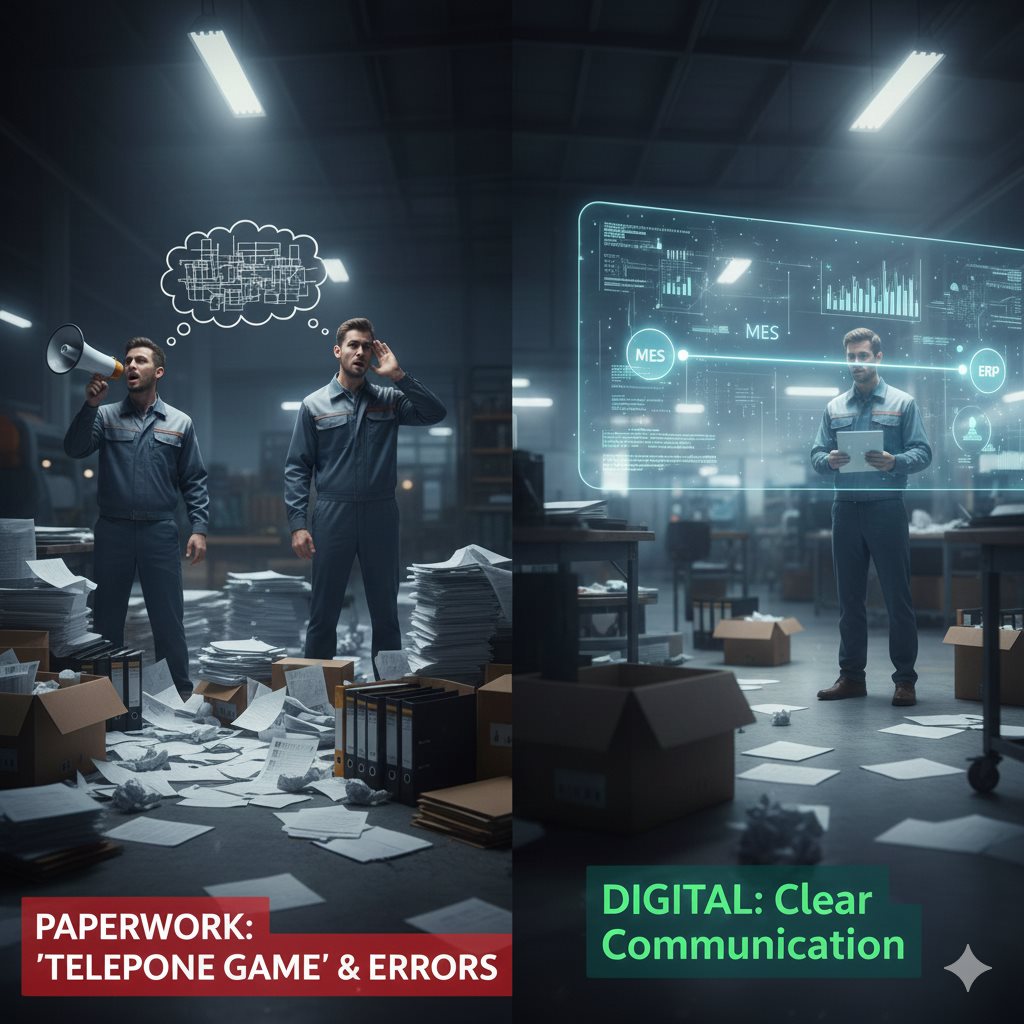

The "Telephone Game" Effect: Why Humans Are Bad Modems

Remember the childhood game "Telephone"? One person whispers a phrase to the next, and by the time it reaches the end of the line, "The cat sat on the mat" has become "The bat spat on the rat."

Manual data entry in manufacturing works exactly the same way, but with much higher stakes.

- The Source: An operator reads a digital gauge on a machine: 10.54mm.

- The Transcription: The operator writes it on a greasy clipboard. Maybe their handwriting is messy, or they round it to 10.5mm.

- The Collection: A supervisor collects the clipboard at the end of the shift. Maybe a page gets torn or coffee gets spilled on it.

- The Digitization: An admin types it into the ERP system the next morning. They are tired, reading messy handwriting, and they typo it as 105mm.

Suddenly, your quality system flags a massive failure that never happened. Or, far worse, the operator wrote down a "passing" number for a failing part because they knew what the number should be, not what it was.

Studies consistently show that human data entry has an error rate of about 1% to 4%. In a factory generating thousands of data points a day, that is dozens of errors entering your system every single day. Over a year, your database becomes a swamp of inaccuracies.

The "Delayed GPS" Problem: Driving Blind

Imagine trying to drive your car using a GPS that only updates your position once every 24 hours. You turn left because the map says the road is clear, only to find out tomorrow that you drove off a cliff.

Running a factory on paper is like driving with a delayed GPS.

- The Problem: You find out about a machine breakdown, a material shortage, or a quality drift 24 hours after it happened (when the paper reports are finally processed and analyzed).

- The Consequence: You cannot react. You cannot fix it. You can only do a "post-mortem" on why you lost money yesterday.

Real-time decision-making requires real-time data. If you are relying on yesterday's numbers, you are always fighting yesterday's fires instead of preventing today's.

The 1-10-100 Rule of Data Quality

The cost of fixing a data error grows exponentially the longer it remains in your system. This is often summarized as the 1-10-100 Rule:

- €1 (Prevention): The cost to verify the data at the source. For example, a digital caliper connected to an MES automatically sends the measurement. If it's out of spec, the system beeps immediately. The cost is negligible.

- €10 (Correction): The cost to fix the error if caught later in the process. The admin notices the "105mm" typo and has to call the supervisor, who has to find the operator, who has to remember what happened yesterday. It wastes an hour of labor.

- €100 (Failure): The cost if the error reaches the customer. You ship the wrong part because your inventory count was off due to a data entry error. Now you are paying for return shipping, replacement parts, and potentially losing the customer entirely.

The Hidden Opportunity Cost

There is another cost that rarely shows up on a balance sheet: Talent Waste.

Your engineers and supervisors are highly paid, skilled professionals. They were hired to solve complex problems, optimize processes, and lead teams.

If they are spending 2 hours a day chasing down paper, verifying numbers, and entering data into spreadsheets, you are paying engineer salaries for data-entry work. That is a massive misuse of human capital.

Furthermore, it leads to burnout. Nobody goes to engineering school because they dream of typing numbers into Excel. Removing the drudgery of manual data entry improves job satisfaction and retention.

Eliminating the Human Variable: Source Data Automation

The solution is not "better training" or "typing faster." The solution is Source Data Automation. This means capturing data directly from the machine or device, bypassing the human brain and fingers entirely.

Examples of Automation:

- Digital Connectivity: Connect your machines (PLCs) directly to your MES. Let the machine report its own cycle count, run time, and error codes every second.

- Smart Tools: Use Bluetooth-enabled torque wrenches and calipers. When the operator completes a task, the tool sends the precise value to the system.

- Barcode/RFID Scanning: Instead of writing "Took 50 screws" on a log, scan the bin. The system deducts the inventory instantly and accurately.

Conclusion

Manual data entry isn't just "old school"; it is a significant business risk. It introduces noise into your data, delays your decision-making, and frustrates your most valuable employees.

By automating data collection, you don't just save time on typing. You gain the confidence that the numbers on your screen actually reflect the reality on your floor. You move from "guessing based on yesterday" to "knowing what is happening right now."