ROI Calculator: See Your Potential Savings

Buying manufacturing software (MES/ERP) is a big decision. The price tag can be intimidating. A CFO looks at the quote and asks, "Why should we spend €50,000 on this? We have Excel, and Excel is free."

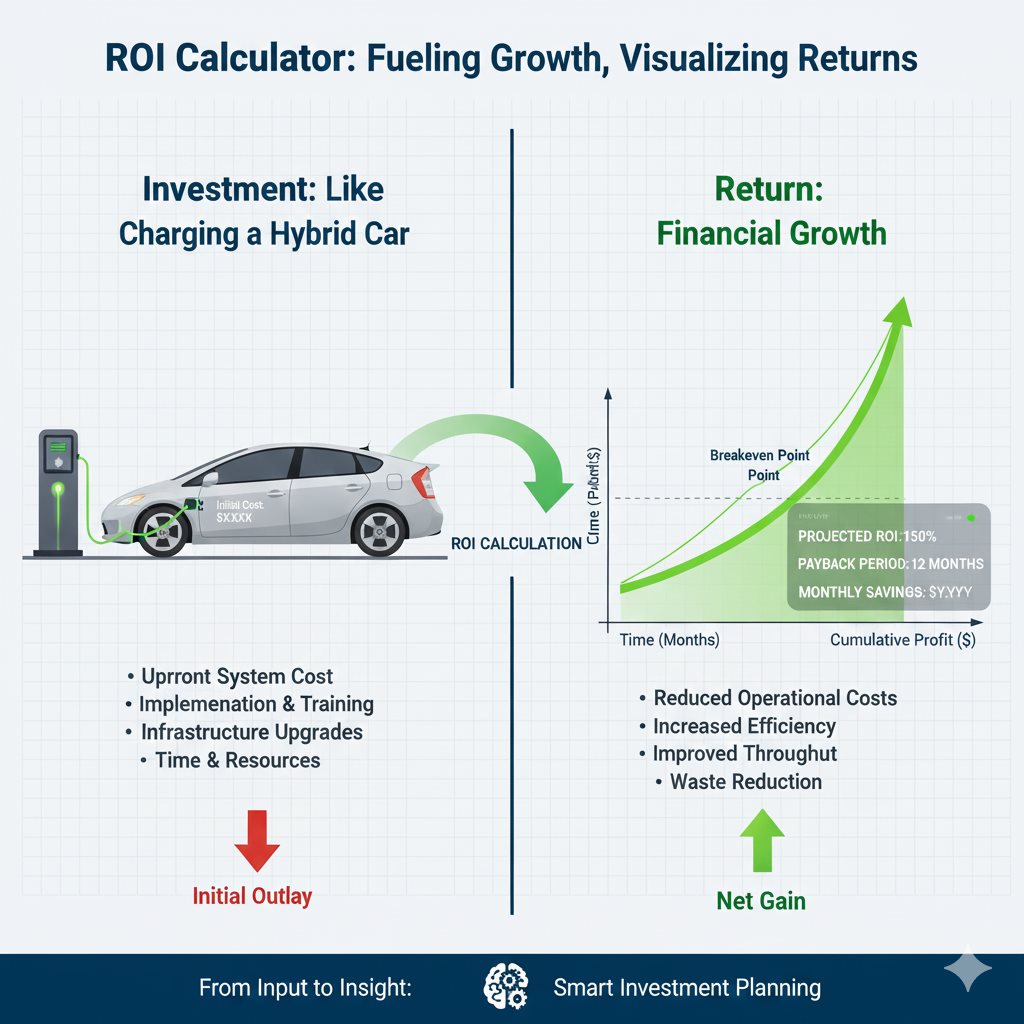

To get approval, you need to speak the CFO's language. You need to talk about ROI (Return on Investment). You need to prove that this isn't an expense; it's an investment that pays for itself.

The Hybrid Car Analogy

Think about buying a car for a delivery business.

- Car A (Old Clunker): Costs €5,000. Gets 10 miles per gallon. Breaks down once a month.

- Car B (New Hybrid): Costs €25,000. Gets 50 miles per gallon. Never breaks down.

If you only look at the sticker price, Car A wins. But if you drive 50,000 miles a year, Car B is actually cheaper because you save thousands on gas and repairs.

Excel is the Old Clunker. It's "free" to buy, but expensive to run (errors, manual data entry time, delayed decisions). MES is the Hybrid. It costs more upfront, but it saves you money every single hour the factory runs.

The 3 Buckets of Savings

Where does the money actually come from?

1. The "Hard" Savings (Scrap & Rework)

This is the easiest to calculate.

- Current State: You scrap 3% of your production due to errors (wrong material, missed step, bad settings).

- Future State: MES error-proofing reduces scrap to 1%.

- The Math: If your annual material cost is €5M, saving 2% is €100,000/year.

2. The "Soft" Savings (Labor Efficiency)

This is about time.

- Current State: Operators spend 15 minutes per shift writing logs and looking for paperwork. Supervisors spend 1 hour per day typing data into Excel.

- Future State: Data collection is automated.

- The Math: 15 mins x 20 operators x €25/hr = €30,000/year in recovered productivity. (Note: You don't fire the operators; you use that time to make more parts).

3. The "Hidden" Savings (Uptime & Capacity)

This is the biggest one.

- Current State: Your OEE (Overall Equipment Effectiveness) is 60%. You are thinking about buying a new €500,000 machine to increase capacity.

- Future State: MES visibility helps you identify bottlenecks and reduce downtime, raising OEE to 70%.

- The Math: You just unlocked 10% more capacity without buying the new machine. You saved €500,000 in CapEx.

Calculating the Payback Period

- Total Investment: €50,000 (Software + Implementation).

- Total Annual Savings: €130,000 (€100k Scrap + €30k Labor).

Payback Period = Investment / Monthly Savings €50,000 / (€130,000 / 12) = 4.6 Months.

Conclusion

Most MES implementations pay for themselves in less than 6 months. After that, everything is pure profit.

When you present this to your CFO, don't just show them the quote. Show them the math. Show them that not buying the system is actually costing the company €10,000 every month in waste.