Quality Management Systems: In-Process vs. End-of-Line

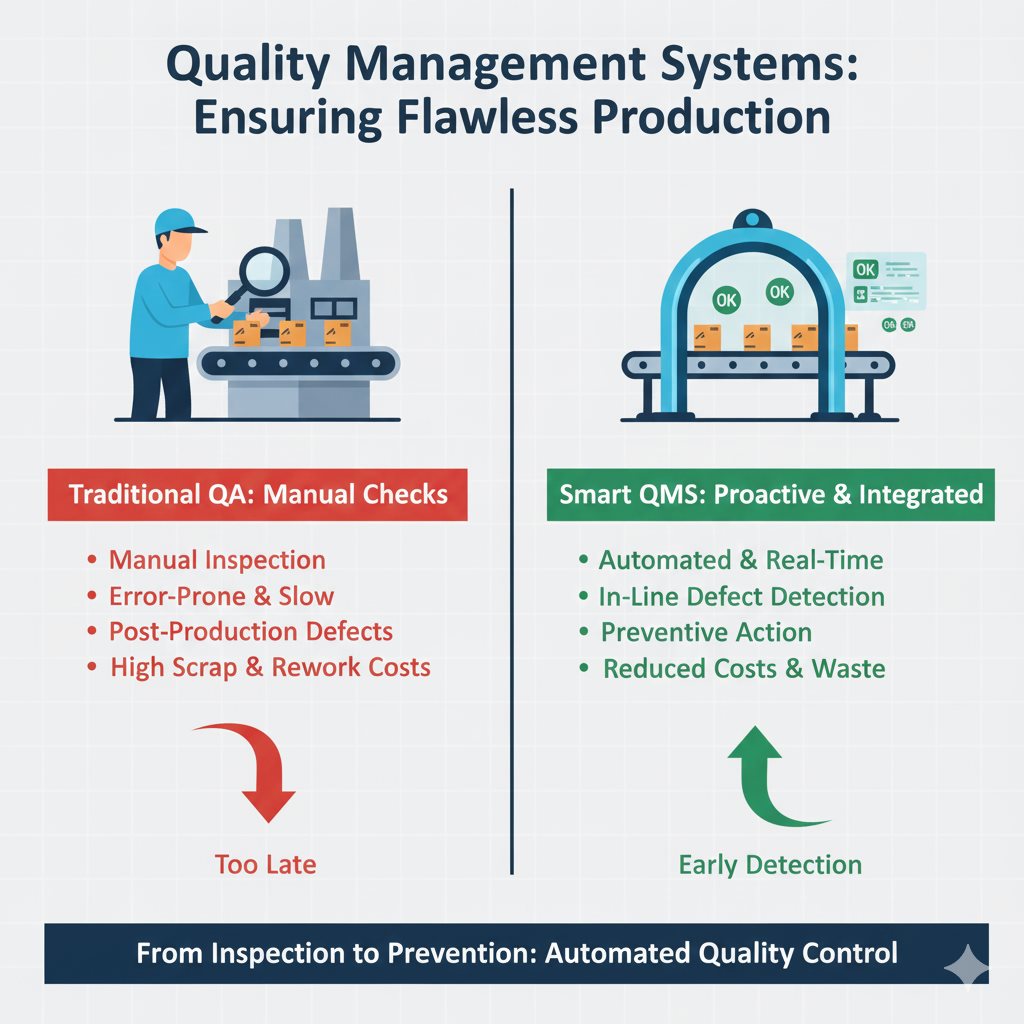

There are two main philosophies when it comes to quality control in manufacturing.

- End-of-Line (EOL): Inspect the product after it is finished.

- In-Process (IPQC): Inspect the product while it is being made.

Many factories rely heavily on EOL because it feels "safer" to check the final result. However, this is often the most expensive way to ensure quality.

The Airport Security Analogy

Think about flying on an airplane.

Scenario A (In-Process): The TSA Checkpoint You go through security before you get to the gate.

- If you have a knife: They catch it immediately. You are removed from the line.

- Cost: Low. You haven't boarded the plane yet. The plane doesn't have to turn around.

Scenario B (End-of-Line): Customs at Destination Imagine there was no security at the departure airport. Everyone just walks on. They only check you when you land in the destination country.

- If you have a knife: They catch you after a 10-hour flight.

- Cost: Massive. You wasted a seat on the plane. You wasted fuel. Now they have to fly you back.

End-of-Line inspection is like Customs. You have already spent the money to make the product (materials, labor, machine time, energy). If you find a defect now, you have to throw all that value in the trash.

In-Process inspection is like the TSA. You catch the defect at Step 1. You stop adding value to a bad part.

The "Cost of Quality" Curve

The earlier you catch a defect, the cheaper it is.

- Defect at Step 1: Cost = €1 (Scrap raw material).

- Defect at Step 10: Cost = €10 (Scrap material + labor + machine time).

- Defect at Customer: Cost = €100 (Warranty + Shipping + Reputation).

Why Factories Stick to EOL (and Why It's Wrong)

If IPQC is so much better, why doesn't everyone do it?

- "It slows down production." Operators hate stopping to measure parts.

- "We don't have the tools." It's easier to have one expensive CMM (Coordinate Measuring Machine) in a lab than 50 digital calipers on the floor.

The Counter-Argument: Does IPQC slow down production? Yes, slightly. But does it slow down shipments? No. In fact, it speeds them up because you aren't spending your Friday night reworking 500 bad parts that failed final inspection.

Implementing Effective IPQC

You don't need to check every part at every step. Use a risk-based approach.

- Identify Critical Control Points: Where does the process usually go wrong? (e.g., The crimping station).

- Force the Check: Use an MES to lock the machine. "Operator cannot start Cycle #50 until they measure the crimp height."

- Go/No-Go Tools: Give operators simple tools (like pass/fail gauges) that are fast to use.

- Trend Analysis: Look for drift. If the crimp height is slowly getting lower, stop the machine before it hits the failure limit.

Conclusion

You cannot inspect quality into a product. You can only build it in. End-of-Line inspection is a filter; it separates the good from the bad. In-Process quality is a steering wheel; it keeps you on the road.