MES vs. ERP: What's the Difference?

In the manufacturing software landscape, acronyms abound. Two of the most critical—and often confused—are ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System).

While both systems are essential for a modern manufacturing operation, they serve very different purposes. Understanding the distinction is key to building a technology stack that actually works for your business.

The High-Level Distinction: A Restaurant Analogy

To understand the difference without manufacturing jargon, let's look at a busy restaurant.

ERP is the General Manager (Front of House)

The General Manager focuses on the business side. They:

- Take Reservations & Orders: (Sales Orders) "Table 4 wants two steaks and a pasta."

- Buy Ingredients: (Procurement) "We need 50 lbs of potatoes for next week."

- Manage Payroll: (HR) "Pay the staff."

- Handle the Bill: (Finance) "Here is the invoice for the meal."

The Manager knows what was ordered and who paid for it, but they are not standing over the stove cooking it.

MES is the Head Chef (The Kitchen)

The Head Chef (or the Kitchen Display System) focuses on execution. When the order comes in, they:

- Sequence the Work: (Scheduling) "Start the steaks now, drop the fries in 5 minutes so they finish together."

- Manage Stations: (Resource Management) "Grill station is backed up, move the fish to the oven."

- Quality Control: (Quality) "This steak is medium-well, not medium-rare. Re-fire it."

- Recipe Management: (Work Instructions) "Follow the exact steps for the hollandaise sauce."

If the Manager (ERP) tried to run the kitchen, chaos would ensue. They don't know the grill temperature or that the fryer is acting up. They just know the customer is waiting. The Head Chef (MES) bridges that gap, ensuring the meal is prepared correctly and on time.

Feature Comparison: Head-to-Head

| Feature | ERP (Enterprise Resource Planning) | MES (Manufacturing Execution System) |

|---|---|---|

| Primary Focus | Business Administration | Shop Floor Operations |

| Users | Finance, Sales, Procurement, Executives | Operators, Supervisors, Maintenance, Quality |

| Data Granularity | Transactional (Order level) | Operational (Machine/Part level) |

| Scheduling | Infinite capacity planning (often) | Finite scheduling (real-time constraints) |

| Inventory | Warehouse & Stock levels | WIP (Work in Process) & Line-side inventory |

| Quality | Incoming/Outgoing inspection | In-process control & enforcement |

The "Grey Area": Overlap and Integration

Modern ERPs are expanding their capabilities, and some claim to have "MES modules." Similarly, some MES platforms are adding inventory and scheduling features. This can create confusion.

However, a generic ERP module rarely matches the depth of a specialized MES. An ERP might tell you that a job is finished, but an MES tells you:

- Exactly when it started and stopped.

- Which specific machine and operator performed the work.

- What the temperature and pressure were during the process.

- Why the machine was down for 15 minutes during the run.

Why You Need Both

Trying to run a factory with only an ERP is like trying to drive a car by looking at a map but not through the windshield. You know where you want to go, but you can't see the obstacles right in front of you.

Conversely, running with only an MES gives you great control over the machine, but you might be driving in the wrong direction without the business context from the ERP.

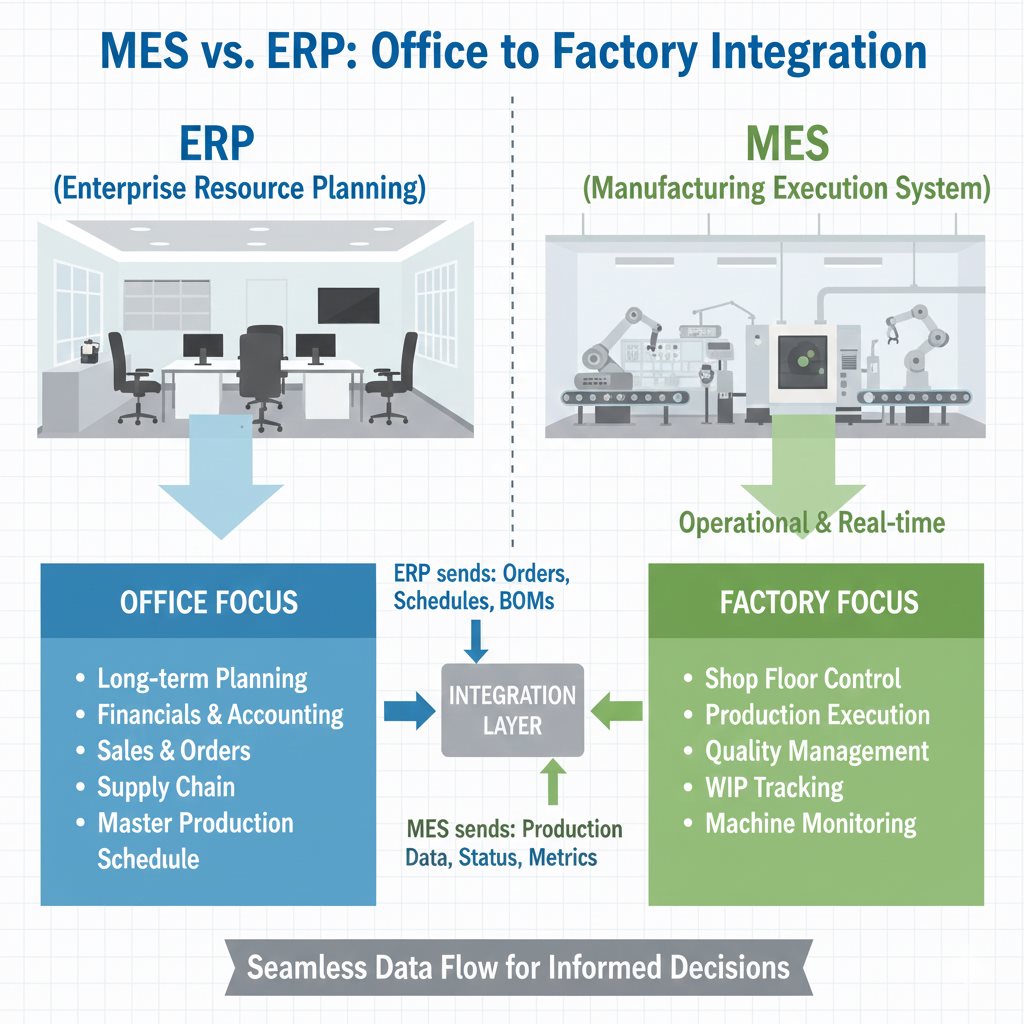

The Ideal Architecture: Integration

The most efficient manufacturers integrate their ERP and MES.

- ERP sends to MES: Production orders, BOMs, and item master data.

- MES executes: Schedules the work, guides the operator, collects data.

- MES sends to ERP: Finished goods counts, material usage, scrap reports, and labor hours.

This closed-loop system ensures that your financial planning (ERP) is always based on the reality of your production floor (MES).

Conclusion

Don't choose between ERP and MES—choose how to make them work together. ERP provides the strategic plan, while MES ensures that plan is executed efficiently, safely, and with high quality.

By implementing both systems in their respective domains, you gain the "top floor to shop floor" visibility required to compete in today's fast-paced manufacturing environment.