ISA-95 Explained: Understanding the Manufacturing Stack

In the world of industrial automation and software, ISA-95 is the gold standard. It is the international standard for the integration of enterprise and control systems. But for many, it remains a complex and abstract concept.

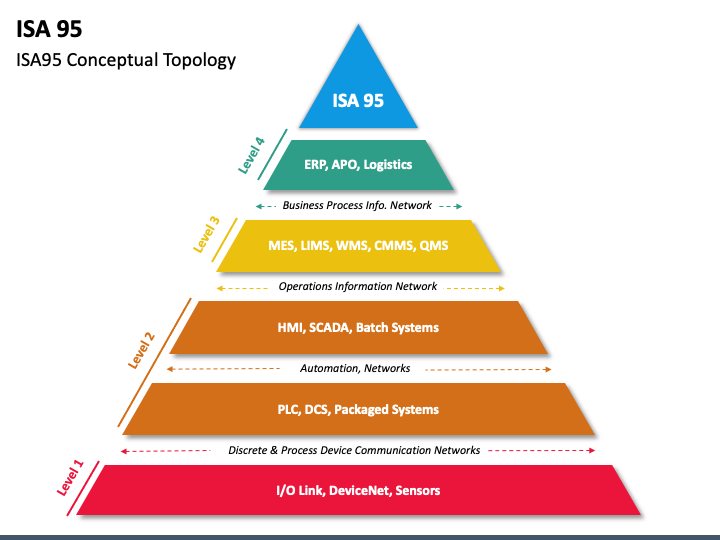

Simply put, ISA-95 provides a model for how different layers of technology in a factory should talk to each other. It defines the "Manufacturing Stack"—a hierarchy of five levels that separates business processes from physical production processes.

Understanding this stack is crucial for designing a scalable, robust manufacturing architecture.

The 5 Levels of the ISA-95 Hierarchy

The standard visualizes manufacturing technology as a pyramid with five distinct levels (0-4).

Level 4: Business Planning & Logistics (ERP)

- What it does: Manages the business. This is where long-term planning, order processing, finance, and purchasing happen.

- Timeframe: Months, Weeks, Days.

- Systems: ERP (Enterprise Resource Planning), CRM, SCM.

- Key Data: Sales orders, material requirements, financial reports.

Level 3: Manufacturing Operations Management (MOM/MES)

- What it does: Manages the workflow to produce the desired products. It coordinates the resources (people, machines, material) to meet the goals set by Level 4.

- Timeframe: Days, Shifts, Hours, Minutes.

- Systems: MES (Manufacturing Execution System), LIMS (Lab Info Management), WMS (Warehouse Management).

- Key Data: Work orders, detailed schedules, quality records, OEE, traceability.

Level 2: Manufacturing Control (SCADA/HMI)

- What it does: Monitors and controls the physical processes. It provides the interface for operators to interact with machines and aggregates data from sensors.

- Timeframe: Minutes, Seconds, Sub-seconds.

- Systems: SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface).

- Key Data: Setpoints, process values (temperature, speed), alarms.

Level 1: Sensing & Manipulation (PLC/DCS)

- What it does: The "brain" of the machine. It reads inputs from sensors and drives outputs to actuators to perform logic control.

- Timeframe: Milliseconds.

- Systems: PLC (Programmable Logic Controller), DCS (Distributed Control System), CNC.

- Key Data: I/O signals, logic states.

Level 0: The Physical Process

- What it does: The actual physical production.

- Timeframe: Real-time continuous.

- Components: Motors, valves, sensors, conveyors, robots.

Why the Layers Matter

The separation of concerns is vital. You don't want your ERP system (Level 4) trying to control a valve (Level 1) directly.

- Security: Isolating the business network from the industrial control network prevents cyber attacks from reaching critical machinery.

- Reliability: If the ERP goes down for maintenance, the factory (Levels 0-3) must keep running.

- Speed: An ERP is too slow to make millisecond decisions required for machine control.

The "Missing Link" Problem

Historically, there has been a massive gap between Level 4 (ERP) and Level 2 (SCADA).

- ERP sends a paper order to the floor.

- Operators manually punch settings into the machine (Level 2).

- At the end of the shift, someone types production counts back into the ERP.

This manual gap is where Level 3 (MES) steps in. It automates the flow of information between the business and the machine.

Modernizing ISA-95: The IIoT Disruption

With the rise of the Industrial Internet of Things (IIoT) and Edge Computing, the strict hierarchy is blurring. Smart sensors (Level 1) can now sometimes push data directly to the cloud (Level 3/4) for analysis.

However, the logical separation remains valid. Even if the data path changes, the distinction between "Business Planning" and "Operational Execution" is fundamental to running a factory.

Conclusion

ISA-95 isn't just a theoretical model; it's a blueprint for integration. By respecting these layers and implementing a robust Level 3 (MES) solution, manufacturers can ensure that their top-floor strategy is perfectly synchronized with their shop-floor reality.