Industry 4.0 for Small Manufacturers: Practical First Steps

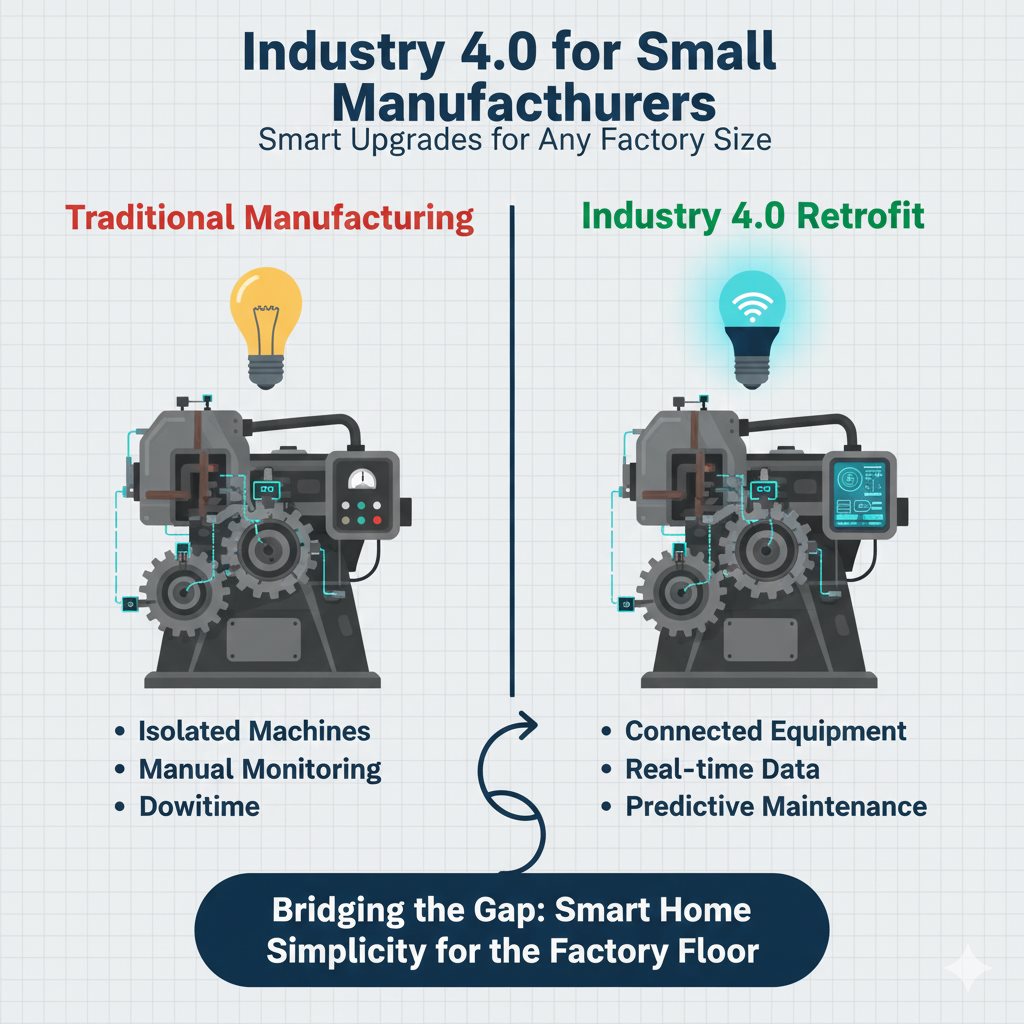

When small business owners hear "Industry 4.0," they often imagine robots doing backflips, AI supercomputers, and a price tag with six zeros. They think, "That's for Tesla or Boeing, not for my 50-person machine shop."

This is a dangerous misconception. Industry 4.0 is not about buying expensive robots; it is about using data to make better decisions. And that is something every business needs, regardless of size.

The Smart Home Analogy

Think about the evolution of the home.

- Industry 2.0 (Electricity): You have light switches on the wall. You walk over, flip the switch, and the light turns on.

- Industry 3.0 (Automation): You install a timer so the porch light turns on automatically at 6 PM.

- Industry 4.0 (Connectivity): You buy a €15 smart bulb. Now, you can control the light from your phone, change the color based on the weather, or have it flash when your Uber arrives.

The Key Insight: You didn't have to rebuild your entire house to get the smart bulb. You just screwed it into the existing socket.

The same applies to manufacturing. You don't need to throw away your old CNC machines or injection molders. You can "screw in" smart sensors and software to make them intelligent.

Step 1: The "Fitbit" for Machines

The easiest entry point is machine monitoring.

- The Problem: You don't know exactly how much your machines are running. Operators say "we were busy all day," but production numbers are low.

- The Solution: Install a simple current sensor (clamp-on) or a light tower sensor on your legacy machines. Cost: <€500 per machine.

- The Result: You instantly see a dashboard showing Green (Running) vs. Red (Stopped). You realize that the "busy" machine actually sat idle for 45 minutes because the operator was waiting for material.

Step 2: Digital Work Instructions (The "YouTube" Effect)

Paper binders are where knowledge goes to die.

- The Problem: You hire a new Gen Z employee. You hand them a dusty 50-page manual. They stare at you blankly.

- The Solution: Put a tablet at the station. Show them a 30-second video clip of how to load the part.

- The Result: Training time drops by 50%. Quality errors due to "I didn't know" disappear.

Step 3: Cloud-Based MES (The "Netflix" Model)

In the past, buying manufacturing software meant buying a server, hiring an IT guy, and paying €100k upfront.

- The Problem: Small shops can't afford the capital expenditure (CapEx).

- The Solution: SaaS (Software as a Service). You pay a monthly subscription per user, just like Netflix.

- The Result: You get enterprise-grade tools (scheduling, inventory, quality) for the price of a daily coffee. If it doesn't work, you cancel. Low risk.

The "Low-Hanging Fruit" Strategy

Don't try to build a "Dark Factory" (fully automated) overnight. Start with the pain points.

- Is scrap killing you? Add digital quality checks.

- Is downtime killing you? Add machine monitoring.

- Is inventory chaos killing you? Add barcode scanning.

Conclusion

Industry 4.0 is a democratizing force. Technology that was once exclusive to the giants is now accessible to the garage shop. The question is not "Can I afford to do this?" but "Can I afford to compete with the shop down the street that is already doing it?"