FIFO vs. FEFO: When to Use Each and Why It Matters

Managing inventory in a warehouse is a lot like managing your home kitchen, but with much higher stakes. If you grab the wrong milk carton at home, you might spoil a bowl of cereal. If a factory grabs the wrong chemical barrel, they might spoil a million-dollar production run or cause a safety incident.

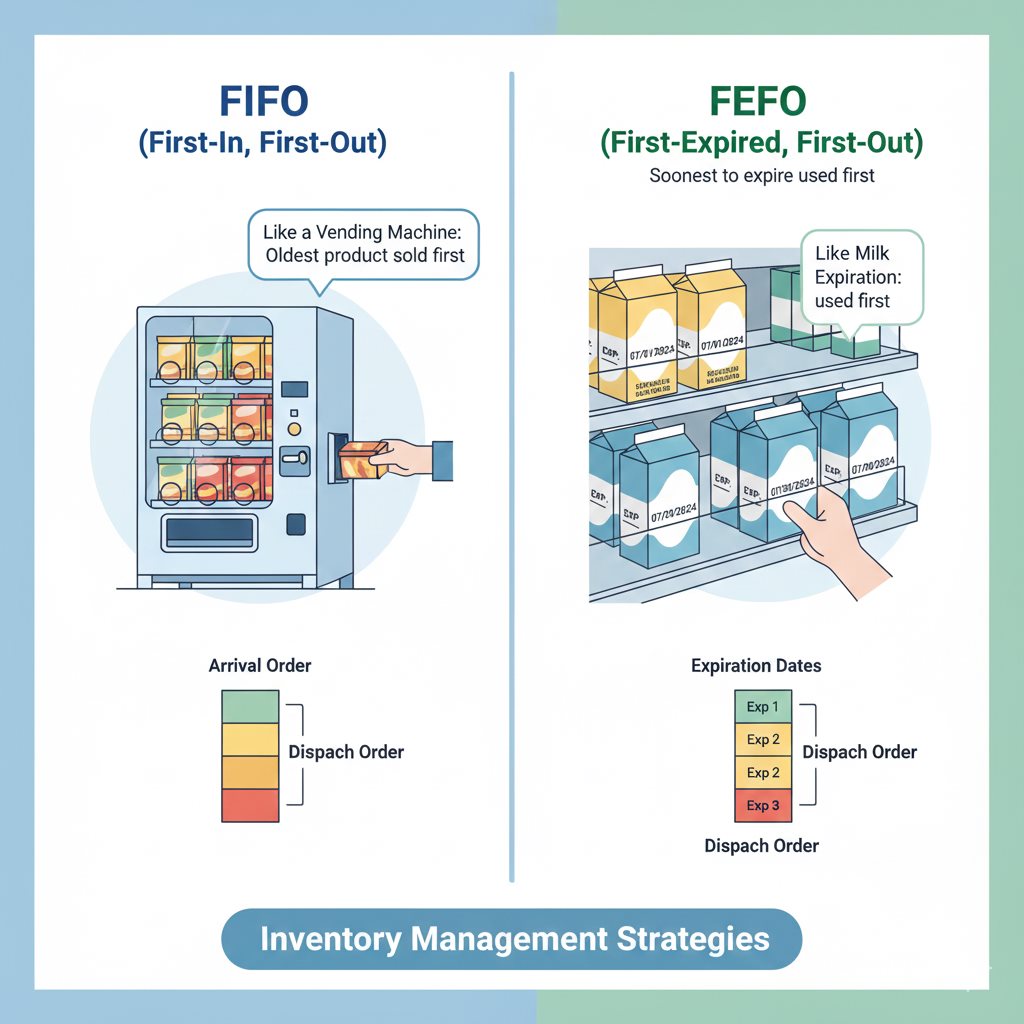

Two acronyms dominate the world of inventory control: FIFO and FEFO. While they sound similar, they represent fundamentally different philosophies about how materials should flow through your facility. Understanding the difference is critical for reducing waste, ensuring quality, and maintaining compliance.

The Towel Stack (FIFO) vs. The Vending Machine

To understand FIFO (First-In-First-Out), think about a vending machine. When the delivery person restocks the soda, they load the new cans from the back. This pushes the older cans to the front. When you buy a soda, you are getting the one that has been there the longest.

This is good! It ensures that inventory rotates.

Now, contrast this with LIFO (Last-In-First-Out). Think of a stack of clean towels in your bathroom cabinet. When you do laundry, you put the fresh towels on top of the stack. When you need a towel, you take one from the top. The towel at the bottom of the stack? It might sit there for years, turning yellow and dusty.

In manufacturing, LIFO is almost always bad for physical inventory (though accountants sometimes use it for tax reasons). You want to be a vending machine, not a towel stack.

When to use FIFO:

- Non-perishable goods: Screws, plastic pellets, metal sheets, electronics, packaging materials.

- Why: Even "non-perishables" degrade over time. Metal rusts. Plastic becomes brittle. Electronics accumulate dust. Packaging glue dries out. FIFO ensures that nothing sits in your warehouse forever, reducing the risk of obsolescence.

The Milk Carton (FEFO)

Now, let's look at your fridge. You have two cartons of milk.

- Carton A: Bought yesterday, expires in 3 days.

- Carton B: Bought today, expires in 10 days.

Which one do you drink first? You drink Carton A, because it expires sooner.

This is FEFO (First-Expired-First-Out). It doesn't matter which one arrived at the warehouse first; it only matters which one will die first.

In a perfect world, FIFO and FEFO would be the same (the oldest item usually expires first). But supply chains are messy. You might receive a shipment today that is actually older (closer to expiration) than the shipment you received last week, perhaps because it sat in a distributor's warehouse for a month.

When to use FEFO:

- Perishable goods: Food ingredients, pharmaceuticals, chemicals, glues, sealants, batteries.

- Why: To prevent waste and ensure safety. If you used FIFO, you might ship a "newer" product while an "older" product (with a closer expiration date) rots on the shelf. In industries like Pharma, shipping expired product is a major compliance violation.

The "Hidden" Expiration Dates

Many manufacturers think they don't need FEFO because they don't make food. But look closer at your Bill of Materials. "Expiration" takes many forms:

- Electronics: Solder paste has a strict shelf life and must be refrigerated. If you use old paste, the joints will fail.

- Aerospace: Pre-preg carbon fiber must be kept in a freezer and used within a specific window.

- Automotive: Rubber seals, gaskets, and tires can "dry rot" if stored too long.

- Chemicals: Some catalysts lose potency over time, affecting the reaction rate in your process.

Implementing This in Software: The Role of the WMS

You cannot do FEFO with a clipboard. Humans are bad at calculating dates on the fly, and they will naturally grab the box that is easiest to reach (which is usually the newest one!).

You need a Warehouse Management System (WMS) or MES that knows the expiration date of every single batch.

The Workflow:

- Receiving: When materials arrive, the operator scans the vendor label. The system records the Lot Number and Expiration Date.

- Picking: When a job needs material, the system calculates which specific lot to use based on the FEFO logic.

- Directed Action: The scanner tells the operator: "Go to Bin A12 and pick Lot #555."

- Validation: If the operator tries to pick Lot #666 (which is newer or easier to reach), the scanner screams: "WRONG LOT! Pick the expiring one first!"

The Hybrid Approach

Sophisticated operations often use a hybrid approach.

- Use FEFO for all shelf-life sensitive materials (chemicals, batteries).

- Use FIFO for durable components (casings, screws).

This requires a system flexible enough to define rules at the part number level.

Conclusion

- FIFO is for preventing obsolescence (dusty towels).

- FEFO is for preventing spoilage (sour milk).

Choosing the right strategy—and enforcing it with software—is the easiest way to stop throwing money (and product) into the trash. It turns your warehouse from a "storage unit" into a dynamic flow engine.