Contract Manufacturing: Managing Customer-Specific Requirements

Being a Contract Manufacturer (CM) is like being an actor who has to play five different characters in the same play.

- Customer A (Automotive) wants strict PPAP documentation and ISO/TS 16949 compliance.

- Customer B (Medical) demands FDA 21 CFR Part 11 traceability and cleanroom logs.

- Customer C (Consumer Goods) just wants it cheap and fast, with minimal paperwork.

If you treat them all the same, you will either go broke (over-processing for Customer C) or get sued (under-complying for Customer B).

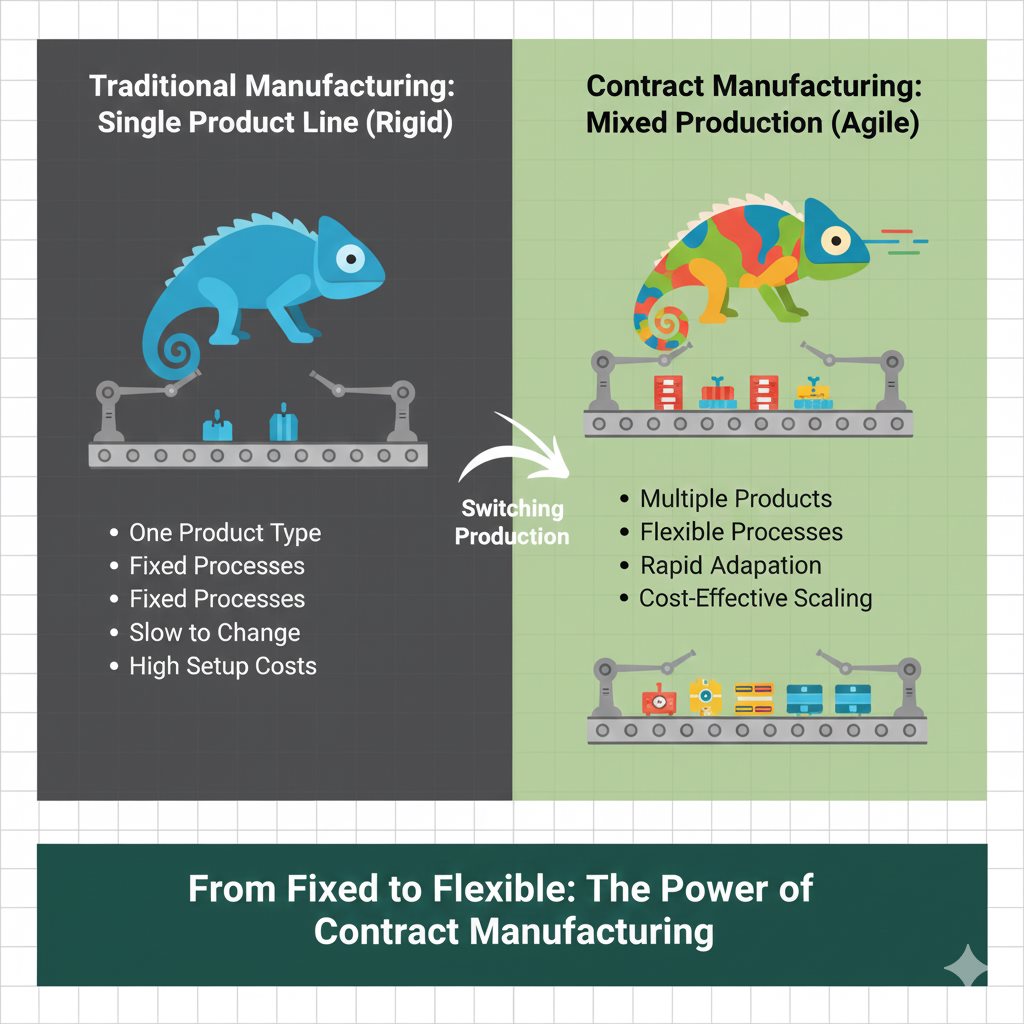

The Chameleon Analogy

A successful Contract Manufacturer must be a Chameleon.

- When you are running Customer A's job, your factory needs to look, act, and report like an automotive factory.

- When you switch to Customer B's job an hour later, you must transform into a medical device facility.

The challenge is: How do you change your "skin" without changing your people, machines, and software every time?

The Trap of "Tribal Knowledge"

In many CM shops, the "Chameleon" logic lives in the head of the Production Manager. "Hey Bob, remember, for GE we have to save the scrap pieces, but for Ford we throw them away."

This is a disaster waiting to happen. Bob will go on vacation. Bob will forget. And you will ship a non-compliant part.

The Solution: Customer-Specific Logic in MES

You need a software system (MES) that enforces the rules per work order, not just per factory.

1. Dynamic Workflows

Your digital traveler should change based on the customer.

- Job 101 (Medical): The system forces the operator to scan their badge, scan the material, and enter a double-password signature before starting the machine.

- Job 102 (Consumer): The system just asks for a "Start" button press.

2. Labeling on Demand

Shipping errors are common in CM. Customer A wants a barcode on the top right. Customer B wants a QR code on the bottom left. Don't rely on operators to remember. The system should auto-generate the correct label format based on the "Customer ID" linked to the order.

3. Segregated Inventory

"Customer Owned Material" is a nightmare. You have 500 screws that look identical, but 200 belong to Customer X and 300 belong to Customer Y. You cannot mix them. Your WMS must track ownership. If an operator tries to issue Customer Y's screws to Customer X's job, the scanner should lock them out.

The "Audit-Ready" State

The ultimate test for a CM is the Customer Audit.

- The Nightmare: The auditor arrives. You run around finding paper binders. You pray there are no missing signatures.

- The Dream: You sit the auditor in a conference room. You give them a login to a "Guest Portal" on your MES. They can see only their production data, their quality reports, and their traceability.

You say, "Here is everything. Let me know if you have questions." And you go back to work.

Conclusion

To win in contract manufacturing, you don't just sell parts. You sell confidence. You sell the assurance that you can handle the complexity of 50 different customers without dropping the ball on any of them.