Manufacturing Insights

Expert articles, guides, and industry trends on MES, ERP, Industry 4.0, and manufacturing excellence.

Categories

Tags

Showing 15 of 15 articles

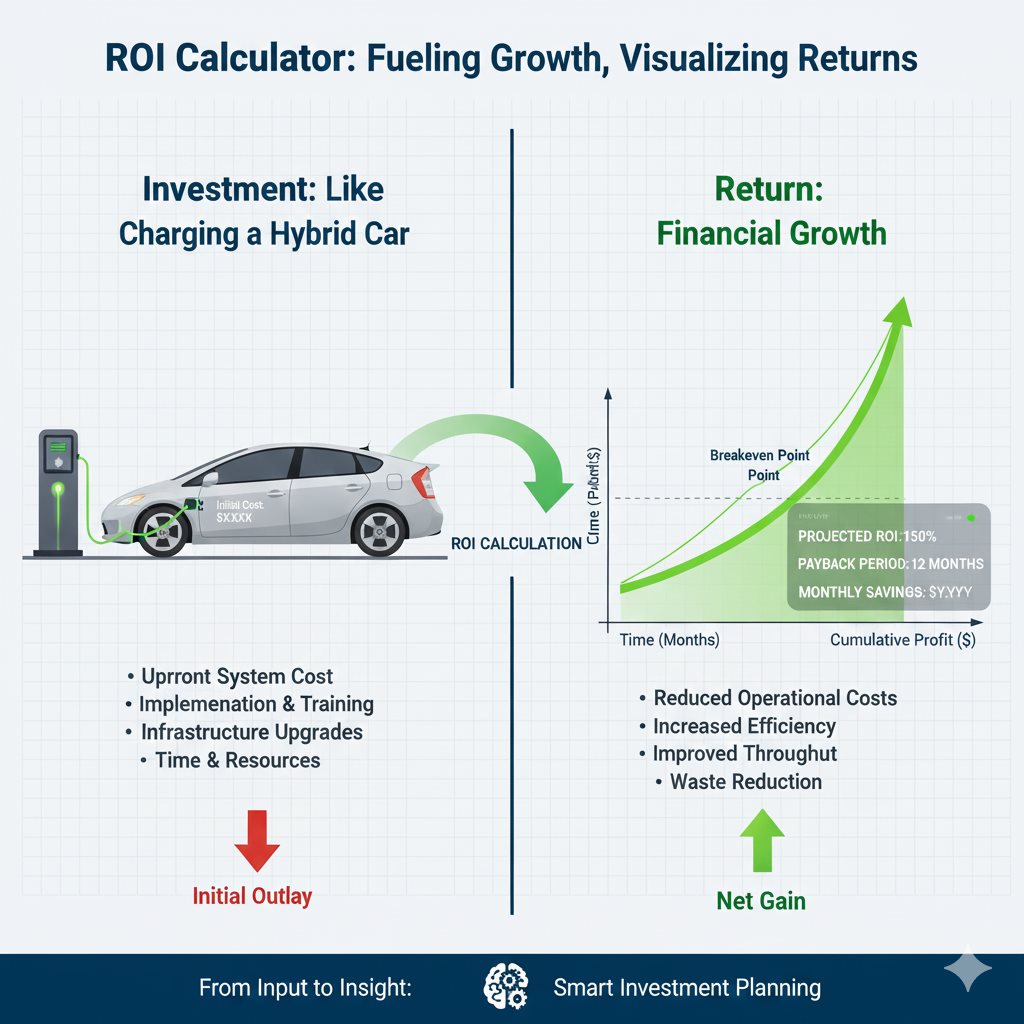

ROI Calculator: See Your Potential Savings

What's the ROI of implementing a Manufacturing Execution System? Learn how to calculate potential savings from reduced scrap, downtime, and labor costs.

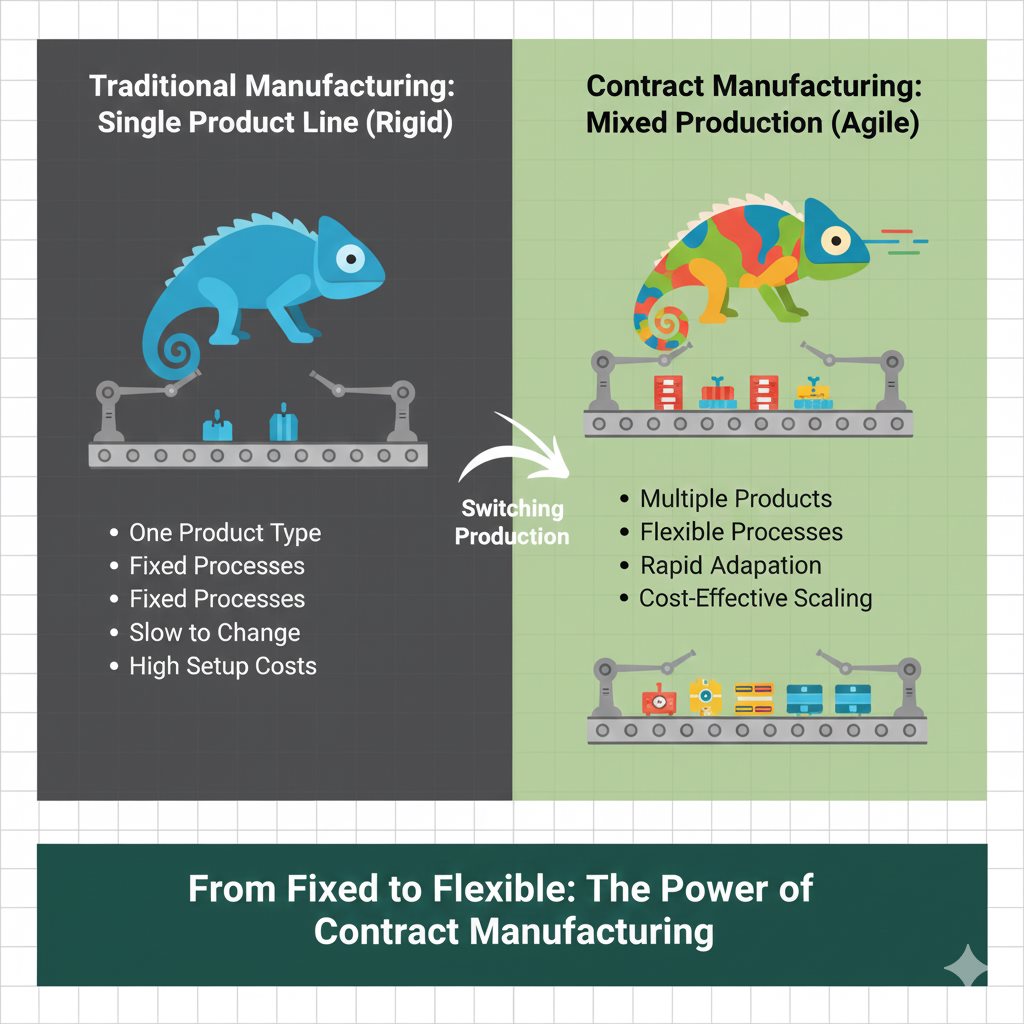

Contract Manufacturing: Managing Customer-Specific Requirements

Contract manufacturers juggle multiple customers and their unique requirements. Learn best practices for managing customer-specific needs, compliance, and traceability.

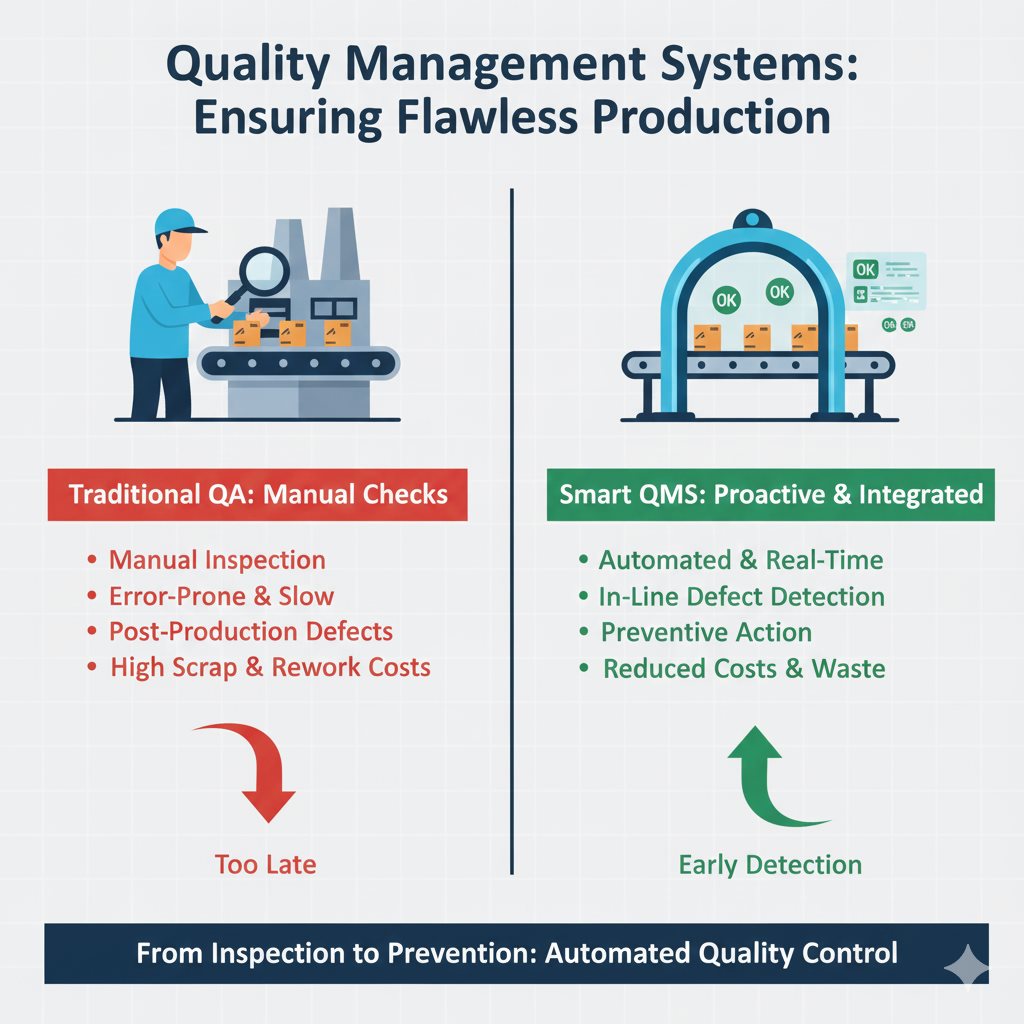

Quality Management Systems: In-Process vs. End-of-Line

In-process quality control vs. end-of-line inspection: Learn the pros and cons of each approach and how to implement the best strategy for your factory.

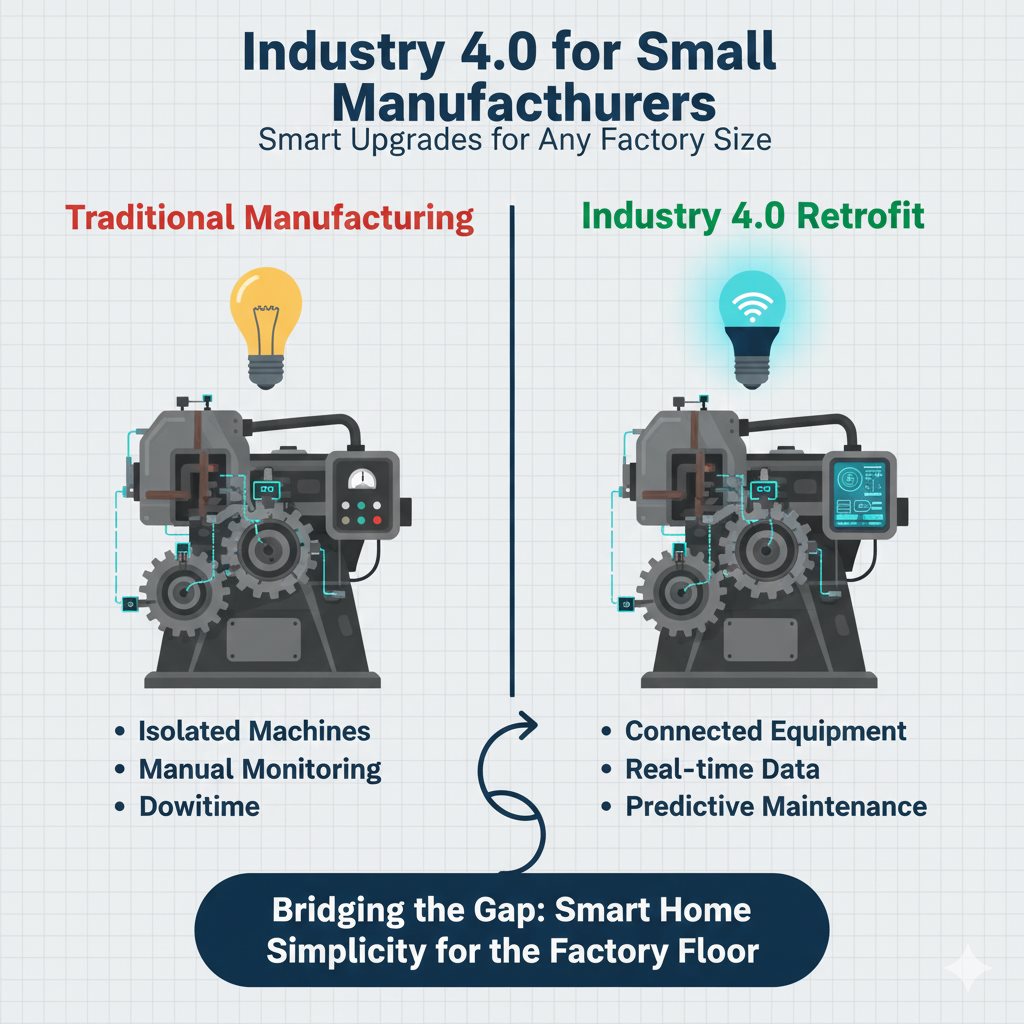

Industry 4.0 for Small Manufacturers: Practical First Steps

Industry 4.0 isn't just for large manufacturers. Learn practical, affordable first steps to implement Industry 4.0 principles in small manufacturing operations.

Real-Time Cost Visibility: From Shop Floor to Finance

Real-time cost visibility enables better financial decisions. Learn how to connect your shop floor to your finance system for instant cost transparency.

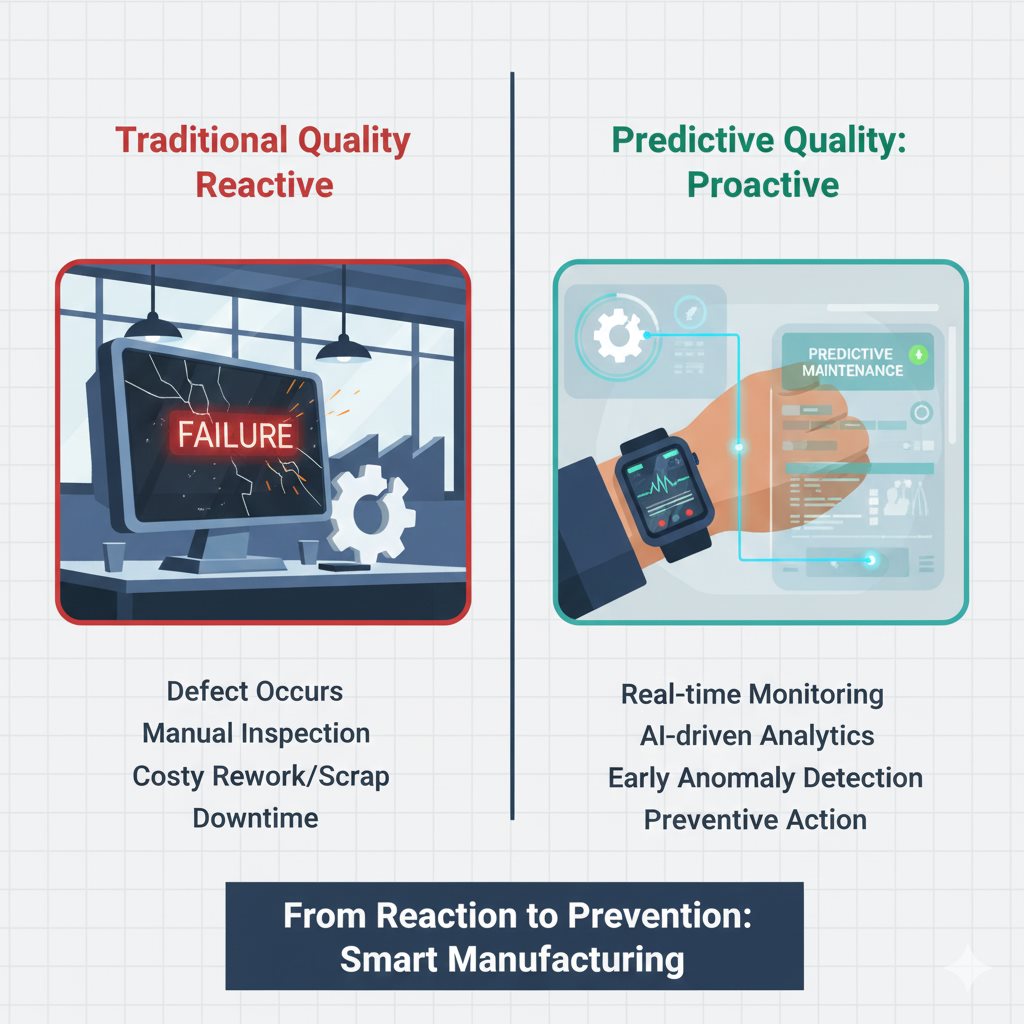

How to Prepare Your Factory for Predictive Quality

Predictive quality uses data and AI to catch quality issues before they become customer problems. Learn how to implement predictive quality in your factory.

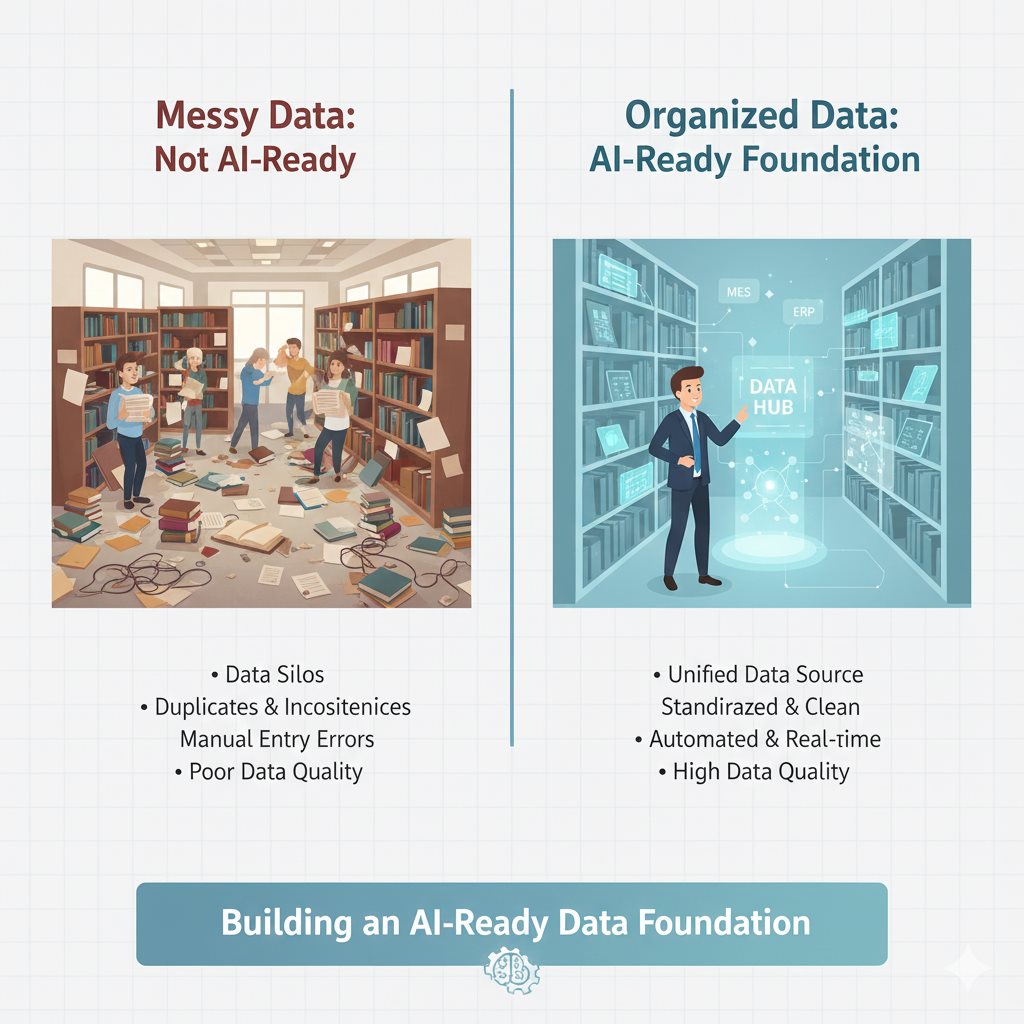

Building an AI-Ready Data Foundation

AI is transforming manufacturing, but only if your data is ready. Learn what constitutes an AI-ready data foundation and how to build it.

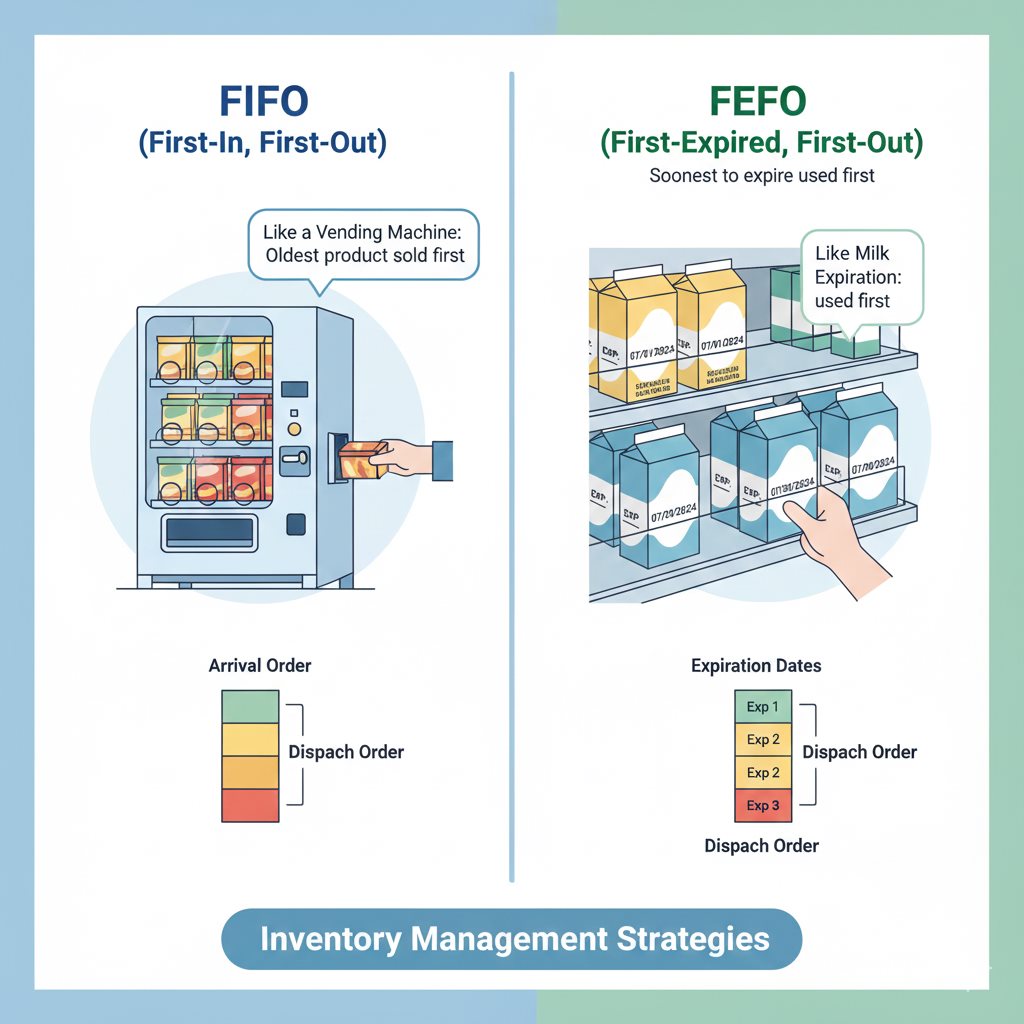

FIFO vs. FEFO: When to Use Each and Why It Matters

FIFO and FEFO are critical inventory management strategies. Learn when to use each method, industry-specific applications, and how they impact your bottom line.

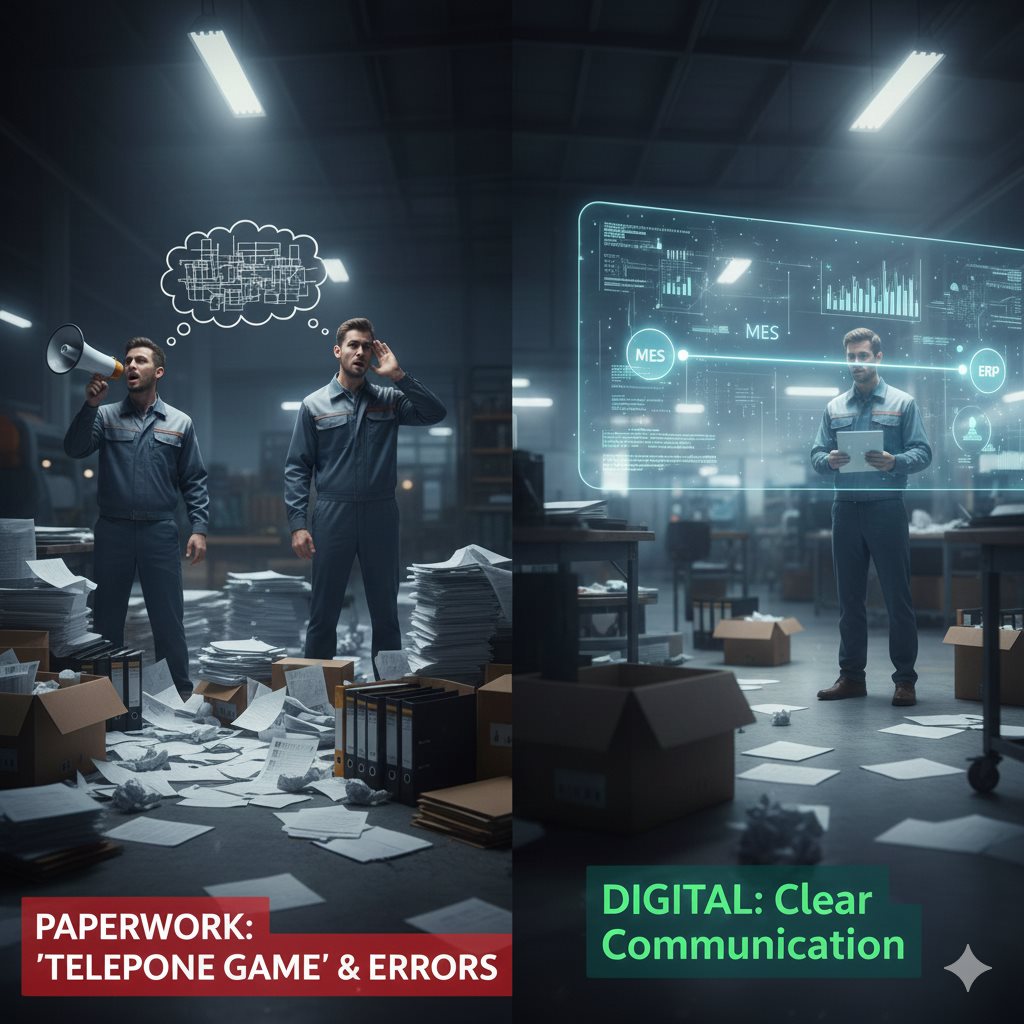

The True Cost of Manual Data Entry (and How to Eliminate It)

Manual data entry costs manufacturers more than just labor. Learn about error rates, compliance risks, and how automation eliminates these costly problems.

How to Achieve 30-Second Traceability

Thirty-second traceability means knowing the status of any production batch in real-time. Discover the systems and practices needed to achieve this level of visibility.

Barcode Traceability: The Foundation of Smart Manufacturing

Barcode traceability is the foundation of Industry 4.0. Learn how to implement barcode systems for complete visibility from raw materials to finished goods.

5 Signs Your Factory Needs Better Production Execution

Is your factory struggling with production delays, quality issues, or lack of real-time visibility? These 5 signs indicate you need a Manufacturing Execution System.

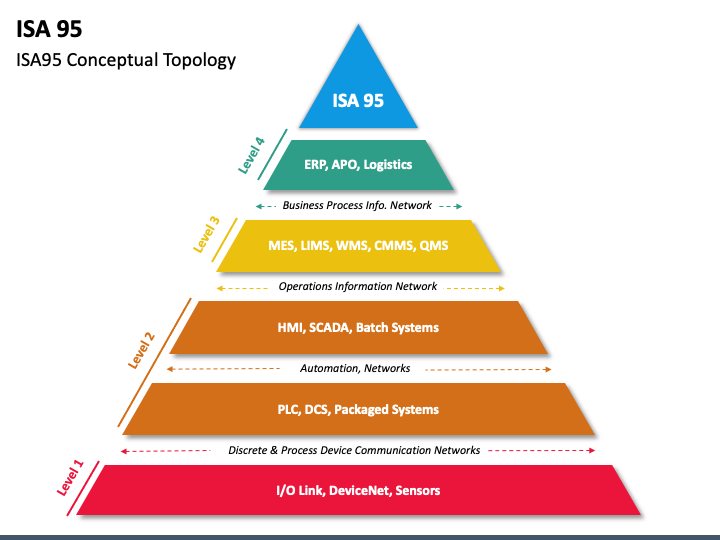

ISA-95 Explained: Understanding the Manufacturing Stack

The ISA-95 standard defines how different manufacturing systems interact. Understand the 5 levels of the manufacturing hierarchy and where TAKT ERP fits.

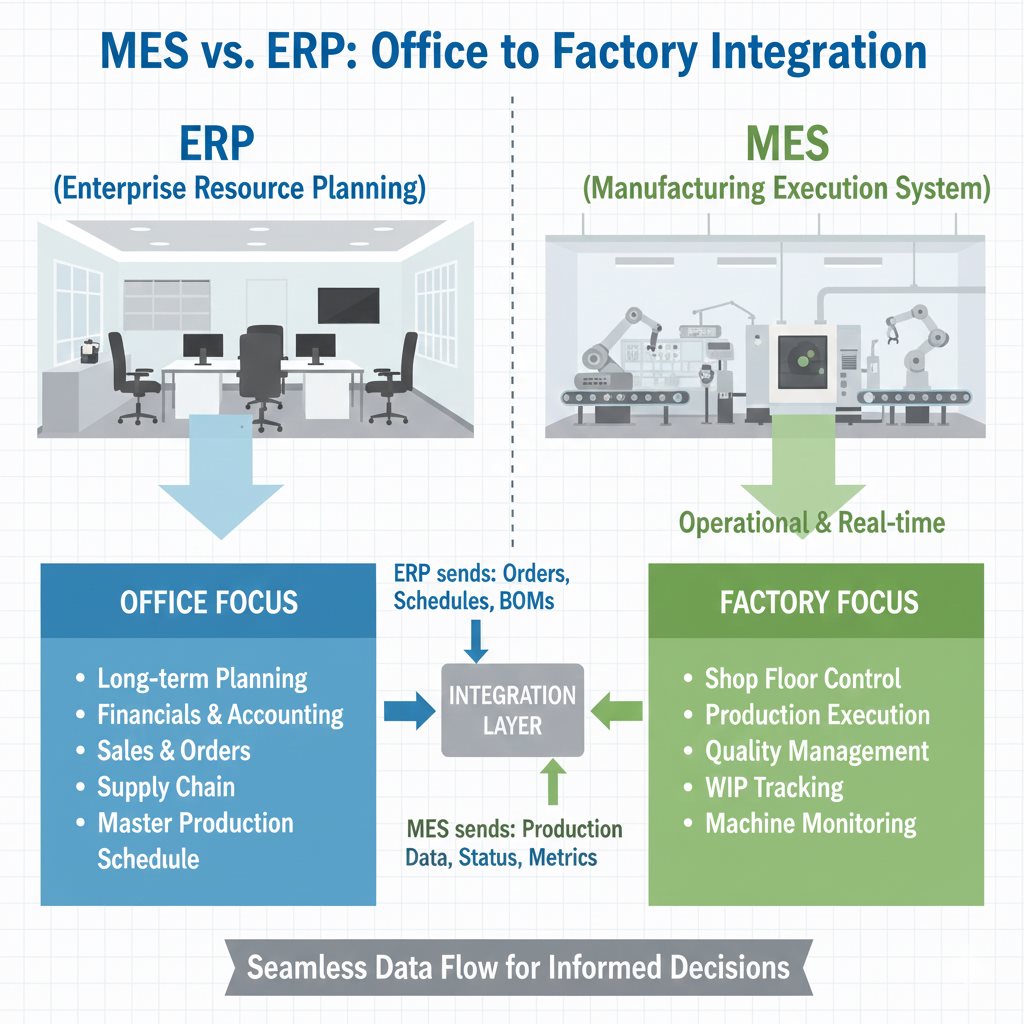

MES vs. ERP: What's the Difference?

Confused about the difference between MES and ERP? This guide explains where each system fits, what they do, and why you need both for complete manufacturing visibility.

What is MES and Why Your Factory Needs It

Learn what a Manufacturing Execution System (MES) is, how it works, and why it's essential for bridging the gap between planning and execution on your shop floor.